The Results

Vaēso & Emperor improved the efficiency, speed, quality & productivity in 13 weeks, achieving impressive results.

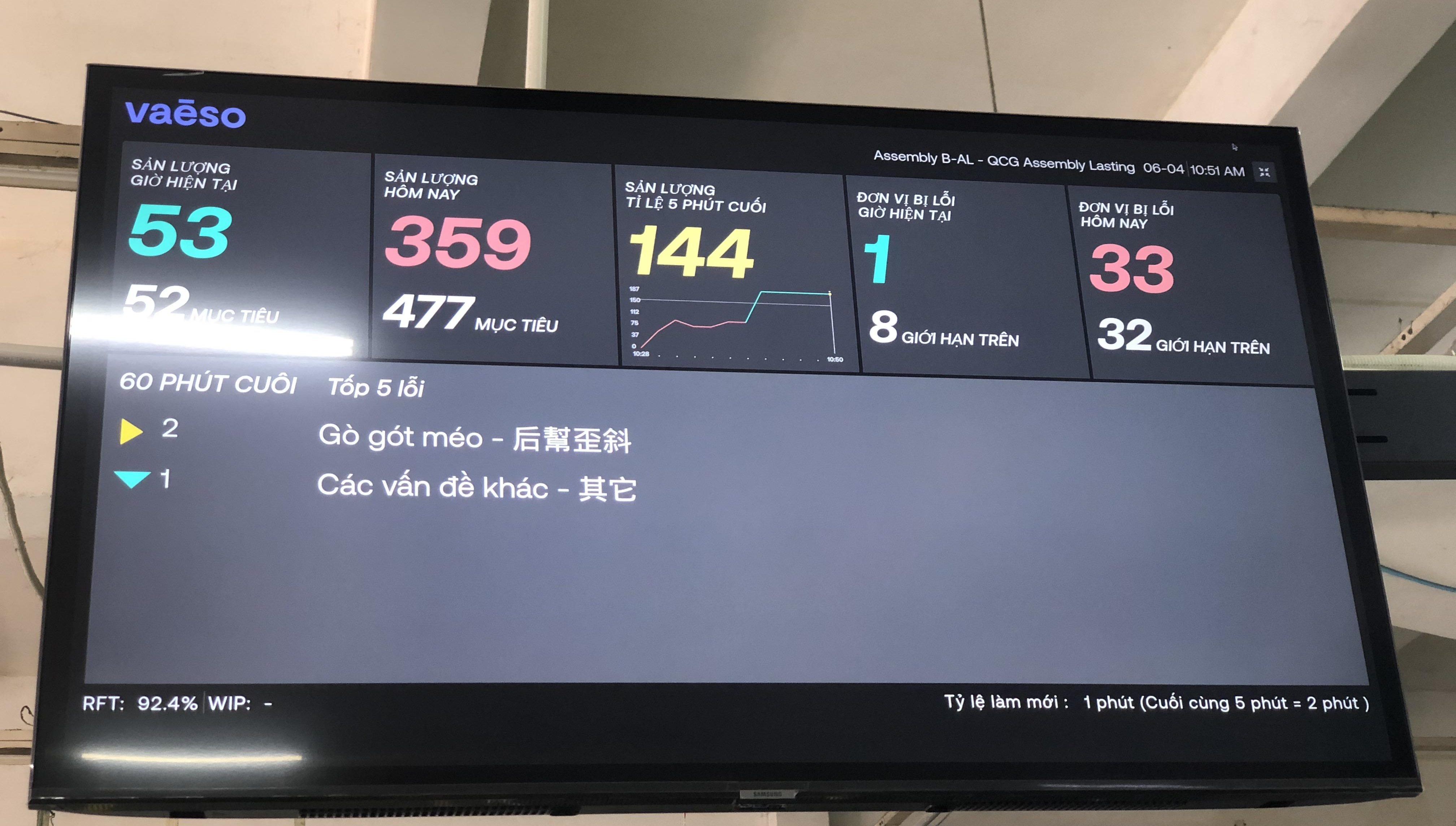

Manufacturing Metrics

o 28% Quality right the first time improvement

o 27% Productivity improvement

Value Creation Financials

o Payback 5 months

The Need

Emperor Footwear Vietnam was founded in 1996 and currently has a total of 2,000 workers manufacturing 220,000 pairs / month for renowned clients such as Geox, Tamaris, Massimo Dutti and Zara Women.

Emperor Footwear has 4 production lines working on casual and fashion ladies and men footwear such as sandals, espadrilles, boots and sneakers.

Emperor identified the following desired outcomes:

o Improve Quality due to the increasing demands of today’s consumers

o Achieve sustainable Efficiency

o Enhance Flexibility to produce smaller orders

o Implement a Reliable and Accurate digital solution to enable quick problem solving

The Solution

1. To transform Emperor Footwear, Vaēso installed its Manufacturing Execution System, LIVE.

2. Each workstation was provided with short range RFID enabled tablets.

3. Visible flat screen TVs were installed across the shop floor displaying real-time dashboards.

4. 100% of materials-components-products were RFID-tagged allowing for automatic real-time product flow tracking.

5. Tablets captured Artisan cycle times, output, productivity and order status, among others.