Manufacturing 4.0 SaaS Solution for the Apparel and Footwear Industry

Transform your brands’ factory ecosystem by providing double-digit improvements in quality, productivity and speed performance metrics.

Ensure a transparent, reliable, traceable, and resilient supply network to drive continuous improvement.

Who Is Vaēso?

Vaēso is powered by Impactiva’s more than two decades of knowledge, experience and know-how that established our industry’s best-in-class quality and factory Lean transformation services.

Learn More %

Right the First Time Quality Improvement

%

Productivity

Improvement

%

Efficiency

Improvement

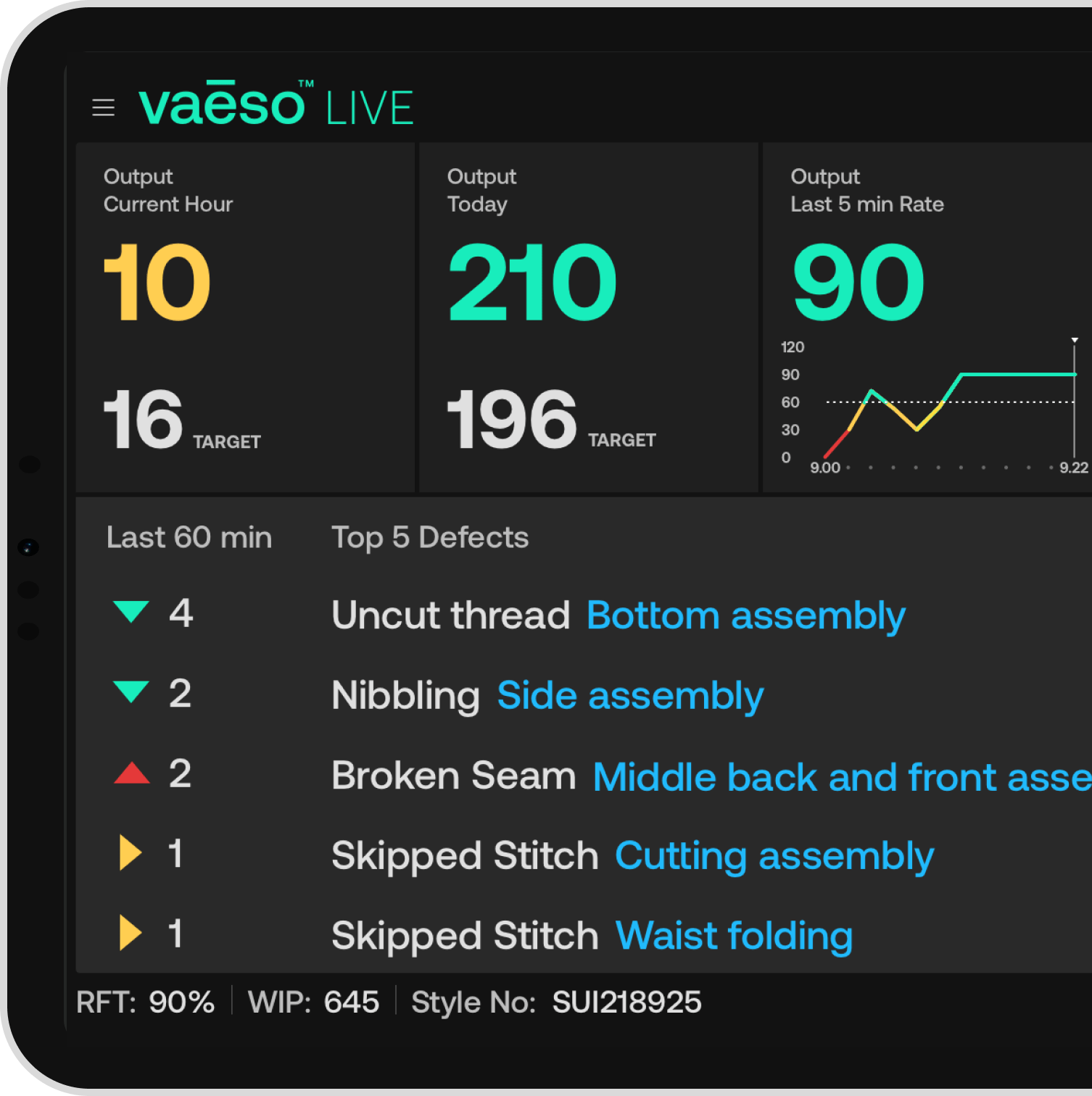

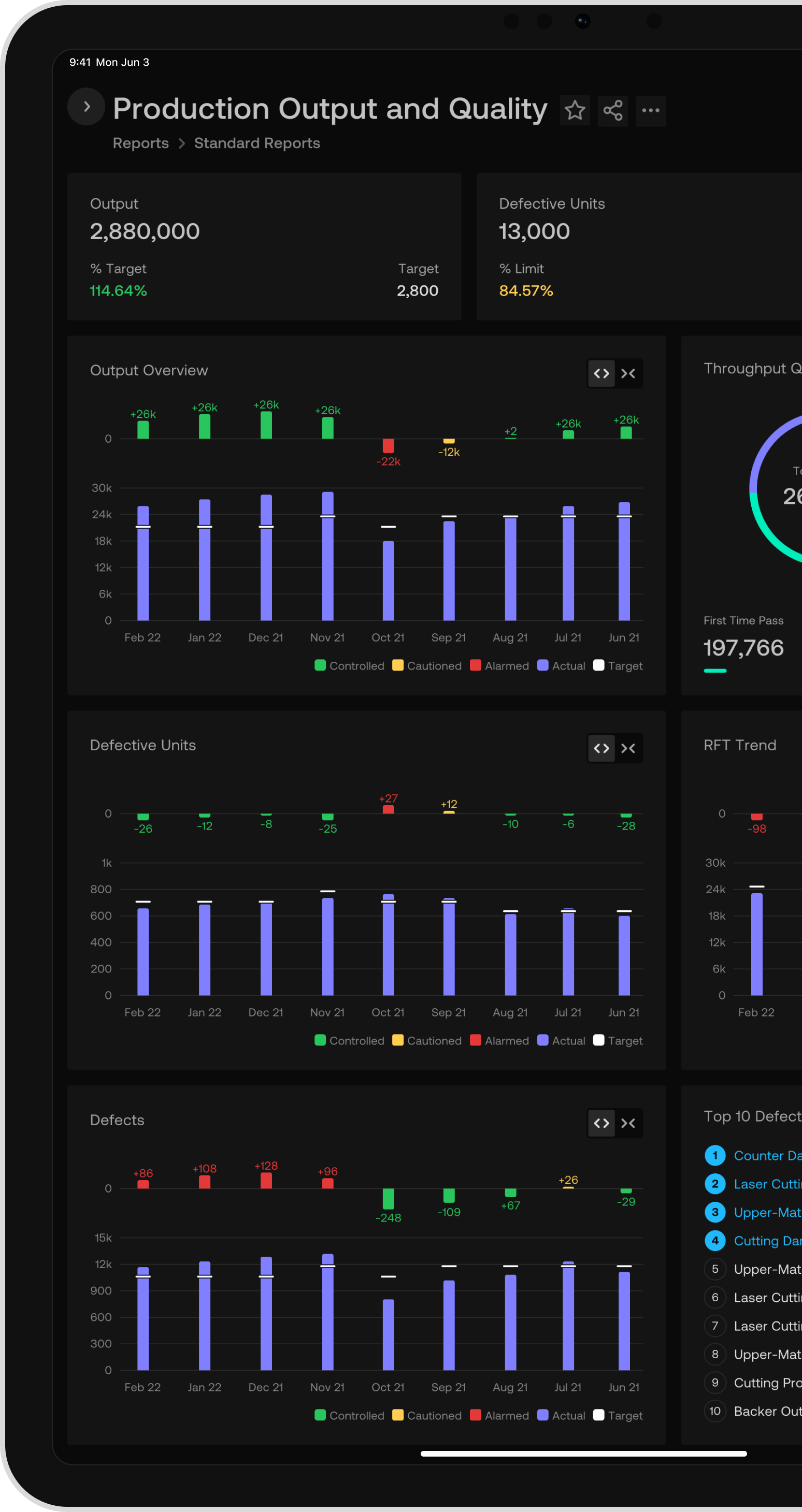

Real-Time Manufacturing Visibility Fuels Agile Decision-Making

Vaēso provides the ability to follow and have accurate details on each product during the manufacturing process, enabling you to have visibility and better control of your production in real time.

Our experience shows that efficiency lags are rooted in traditional manufacturing systems that rely on manual data capture and daily reports. In many instances, factory teams are fixing today’s problems with yesterday’s data.

Real time data allows teams to react in minutes and seconds rather than days and hours. Artisans, line leaders, production and factory management are able tackle issues in real time by continuously monitoring efficiency, quality, and productivity every minute and reacting immediately to shop floor alerts.

Real-Time Metrics Drive Performance And Results

Access your most important manufacturing KPIs based on reliable, accurate and non-sampled data to easily view and analyze current quality, productivity, capacity, efficiency, PO status, and other essential KPIs.

With real time, detailed metrics you can identify areas of improvement to ensure your current operations are performing at their highest levels of capacity, productivity, quality, and speed.

Use Vaēso to visualize data and track long-term comparative patterns and trends that can be shared across both your business and technical team.

Vaēso Platform

Payback Within Months

A fast and efficient implementation coupled with dramatic improvement in quality, productivity and speed, result in an outstanding Return on Investment.

Your Savings with Vaēso

With an Average INCREASE IN PRODUCTIVITY of

%

Total Daily Additional Profits

$

Annualized Additional Profits

$

Savings calculation based on certain assumptions, if you would like to know more details, please contact us.

Vaēso Savings Calculator

INPUT DATA

Vaēso Benefits

Enhance Supply Network performance, visibility, and transparency.

Achieve real-time shop floor visibility using accurate data.

Improve productivity and capacity by up to 50%.

Improve Right the First Time quality by at least 30%.

Reduce lead-times up to 30 days.

Reduce material scrap annually by +10%.